Probabilistic Safety Assessment (PSA)

Radiation and radioactive substances have many beneficial applications, ranging from power generation to use in medicine, industry and agriculture. International Atomic Energy Agency (IAEA), the Atomic Energy wing of United Nations, develops safety standards that reflect a consensus on what constitutes a high level of safety for protecting people and the environment from harmful effects of radiation. Regulating safety is a national responsibility. Many IAEA Member States adopt the IAEA’s safety standards for use in their national regulations. For Nuclear Power Plants, IAEA Safety Standards include a requirement for a safety analysis based on deterministic and probabilistic methods.

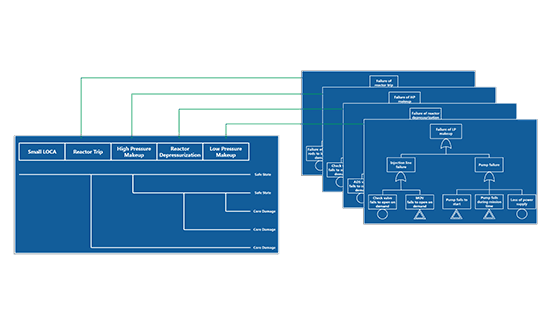

Probabilistic Safety Assessment (PSA), also known as Probabilistic Risk Assessment (PRA), is an established technique to numerically quantify the risk from a nuclear power plant. It provides a methodological approach to identify accident sequences that can follow from a broad range of initiating events and includes a systematic and realistic determination of accident frequencies and consequences.

The objectives of a PSA are to determine all significant contributing factors to the radiation risks arising from a facility, and to evaluate the extent to which the overall design is well balanced and meets probabilistic safety criteria.

PSA answers the following three fundamental questions: (known as “risk triplet”)

- What can go wrong? (Accidents)

- How likely it is? (Likelihood)

- What are the consequences? (Consequences)

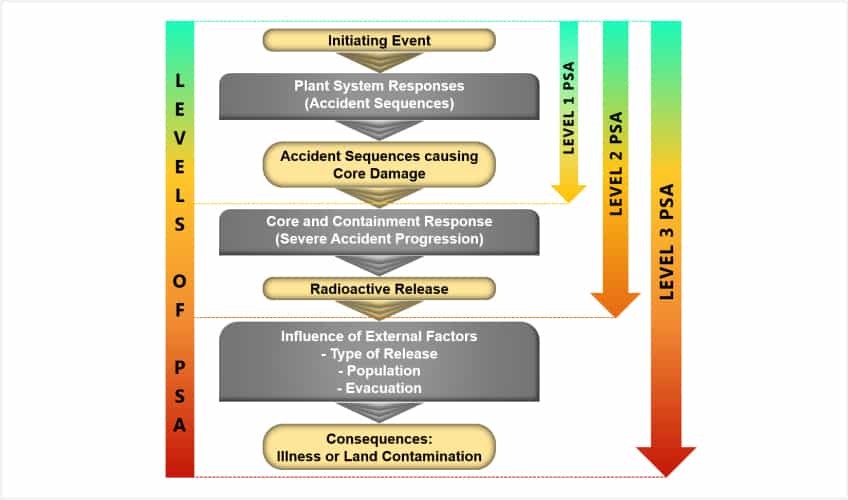

In international practice, three levels of PSA are generally recognized:

- In Level 1 PSA, the design and operation of the plant are analysed in order to identify the sequences of events that can lead to core damage and the core damage frequency is estimated. Level 1 PSA provides insights for design and procedure improvements and into ways of preventing accidents leading to core damage.

- In Level 2 PSA, the chronological progression of core damage sequences identified in Level 1 PSA is evaluated, including a quantitative assessment of phenomena arising from severe damage to reactor fuel. Level 2 PSA identifies ways in which associated releases of radioactive material from fuel can result in releases to the environment. It also estimates the frequency, magnitude and other relevant characteristics of the release of radioactive material to the environment. This analysis provides additional insights into improvements in measures for the mitigation and management of severe accidents.

- In Level 3 PSA, public health and other societal consequences are estimated, such as the contamination of land or food from the accident sequences that lead to a release of radioactivity to the environment. In addition, Level 3 PSA provides insights into the relative effectiveness of aspects of accident management relating to emergency preparedness and response.

Level 1 PSA, Level 2 PSA and Level 3 PSA are sequential analyses, where the results of each assessment usually serve as a basis for the next level.

Deterministic Safety Assessment (DSA)

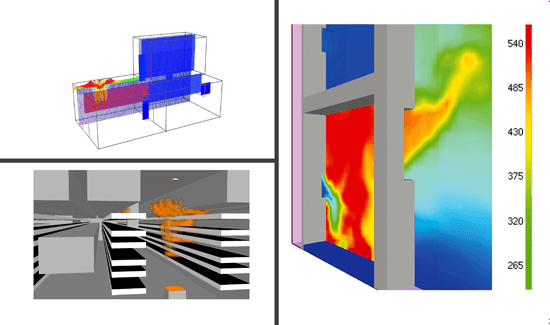

The deterministic safety analysis (DSA) is a characteristic of safety decision making in which results from engineering analyses, not involving probabilistic considerations, are used to support a decision. DSA assumes guaranteed occurrence of some events focusing on accident types, releases and consequences, without considering the probabilities of different event sequences. Typically used with either ‘best estimate’ or ‘conservative’ values, based on expert judgement and knowledge of the phenomena being modelled.

- Deterministic Safety Analysis mainly provides

- Characterization of the postulated initiating events that are appropriate for the site and the design of the plant;

- Analysis and evaluation of event sequences that result from postulated initiating events, to confirm the qualification requirements;

- Establishment and confirmation of the design bases for all items important to safety;

- Comparison of the results of the analysis with acceptance criteria, design limits, dose limits and acceptable limits for purposes of radiation protection;

- Demonstration that the management of anticipated operational occurrences and design basis accidents is possible by the automatic actuation of safety systems in combination with prescribed actions by the operator.

Why PSA?

- Provides a systematic analysis to give confidence that the design will comply with the general safety objectives;

- Demonstrates that a balanced design has been achieved such that no particular feature or Postulated Initiating Event (PIE) makes a disproportionately large or significantly uncertain contribution to the overall risk, and that the first two levels of defence in depth bear the primary burden of ensuring nuclear safety;

- Provides assessment of the probabilities of occurrence and the consequences of external hazards, in particular those unique to the plant site;

- Identifies systems for which design improvements or modifications to operational procedures could reduce the probabilities of severe accidents or mitigate their consequences;

- Identifies functional, spatial and human induced dependencies within the plant configuration;

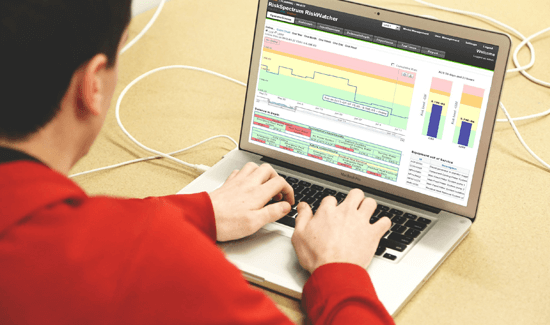

- Supports evaluation and analysis of plant operational events;

- Assists in maintenance optimisation;

- Aids in the assessment of the adequacy of plant emergency procedures;

- Validates compliance with probabilistic targets;

- Helps in decision making process related to back fitting, design modifications and more….